Difference between revisions of "Configuration management"

DavidBeraha (Talk | contribs) (→Summary) |

DavidBeraha (Talk | contribs) (→Definition) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

==Definition== | ==Definition== | ||

| − | + | {{ {{PAGENAME}} }} | |

==Summary== | ==Summary== | ||

| Line 35: | Line 35: | ||

===NKM infrastructure and configuration management=== | ===NKM infrastructure and configuration management=== | ||

| − | Much of the infrastructure technology and systems established for a comprehensive NPP configuration management (CM) system will also support | + | Much of the infrastructure technology and systems established for a comprehensive NPP configuration management (CM) system will also support KM principles, requirements and [[Data|data]]. The technology required to implement an NKM programme is based upon the general technology infrastructure required for nuclear MRO, configuration management and general nuclear business operations. This includes raw data, functionality and plant lifecycle management facilities to capture and maintain the plant design basis, design changes, work management, parts and other functions. The technical means of capturing and managing nuclear knowledge closely resembles that required for nuclear business processes and configuration management. A well-formulated configuration management infrastructure will already have a large portion of the functionality and features required for knowledge management as well, and thus should be part of a greater technology infrastructure and system. The proper CM technology solution offers the ideal facility from which to manage nuclear knowledge and make the most of the data and information collected. |

| − | Assuming the | + | Assuming the NPP has a well-developed technology and information infrastructure as described above, the principal difference between baseline nuclear information systems and those requiring modification for NKM is when no KM features and processes have existed previously. Technology solutions that best support knowledge management should offer the following capabilities: |

* [[Capture]] knowledge as it is utilized and communicated in daily plant activities; | * [[Capture]] knowledge as it is utilized and communicated in daily plant activities; | ||

* Be designed to identify and validate knowledge items, as opposed to data or information. | * Be designed to identify and validate knowledge items, as opposed to data or information. | ||

* Make CM elements determined to be knowledge available, accessible and provided for daily use by all NPP staff; | * Make CM elements determined to be knowledge available, accessible and provided for daily use by all NPP staff; | ||

* All NPP users should understand and be comfortable with the system; | * All NPP users should understand and be comfortable with the system; | ||

| − | * Be based on an NPP — or owner-wide IT solution utilizing a control network such as plant lifecycle management ( | + | * Be based on an NPP — or owner-wide IT solution utilizing a control network such as plant lifecycle management (PLM). |

| − | + | ||

| − | + | ||

===Types of Nuclear Knowledge in NPP's=== | ===Types of Nuclear Knowledge in NPP's=== | ||

Latest revision as of 16:01, 21 December 2015

Contents

- 1 Definition

- 2 Summary

- 3 Description

- 3.1 CM and NKM

- 3.2 Strategic Nuclear Knowledge Management (NKM) Objectives

- 3.3 NKM infrastructure and configuration management

- 3.4 Types of Nuclear Knowledge in NPP's

- 3.5 Nuclear Knowledge Management (NKM) Stages

- 3.6 CM and NKM Convergence in NPP Operations

- 3.6.1 Configuration Management and Nuclear Knowledge Management converge in the following NPP processes:

- 3.6.2 Besides NPP Plant Data, how should these tools for Knowledge Capture and Management be best utilized?

- 3.6.3 Knowledge Management Systems benefit from NPP CM and MRO systems best when you have the appropriate:

Definition

The process of identifying and documenting the characteristics of an organization’s structures, systems and components (including computer systems and software), and of ensuring that changes to these characteristics are properly developed, assessed, approved, issued, implemented, verified, recorded and incorporated into the organization’s documentation.

Summary

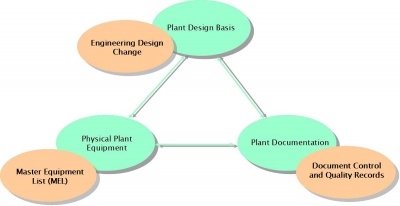

Configuration management (CM) maintains an accurate alignment of facility configuration information and what is actually installed in the physical plant. Any ‘mismatches’ of these three categories of information must be evaluated and corrected if specified by the process owner. When these three aspects of engineering design agree and are synchronized by content and time, they are said to be in “Equilibrium” (Figure 1).

Description

CM and NKM

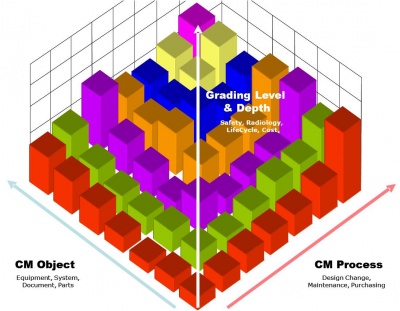

The utilization of configuration management for NKM requires the knowledge and cooperation of all employees for success. It is also used to maintain the plant design bases and also to implement plant modifications. The IAEA-TECDOC-1335, January 2003, ‘Configuration management' and Safety Reports Series No 65, December 2010, 'Application of Configuration Management in Nuclear Power Plants', in nuclear power plants present a basic approach to configuration management. Both documents consider experience gained from discussions at meetings, and from organizations and utilities which have successfully implemented partial or full configuration management programmes. CM is applied according to the impact of equilibrium to a particular discipline or aspect of NPP engineering, maintenance or operation (Figure 2). The amount of CM and Knowledge to be acquired from the process is a direct result of the volume of data and relevance achieved from the data capture.

These documents, when studied in the context of Nuclear Knowledge Management, show that much of the infrastructure technology and systems established for a comprehensive NPP configuration management (CM) system will also support KM principles, requirements and data. The technology required to implement a KM programme is based upon the general technology infrastructure required for nuclear MRO, configuration management and general nuclear business operations.

Strategic Nuclear Knowledge Management (NKM) Objectives

Capture, Process and Publish Critical Nuclear Plant Knowledge to:

- Maximize efficiency, minimize rework and increase standardization

- Quickly and easily store and access the right knowledge and data

- Easily identify and access expertise both within and outside the organisation

- Quickly assimilate new acquisitions and make new local expertise available globally

- Lessons Learned - Learn quickly and in a timely fashion from successes and failures

- Easily retain useful knowledge and avoid “brain drain” as people leave or retire

- Embed Knowledge Management into key work processes to ensure ongoing learning is integral to business and not a “nice to have” bolt on

- Become an organisation where people want to share and create knowledge

How do CM and NKM support each other?

- The convergence of enterprise nuclear MRO and CM information systems with Nuclear Knowledge Management serves as an emerging source for capture and management of key tacit nuclear knowledge.

- Configuration Management Processes and Information Systems are the best source of latent and “passive” knowledge and experience.

- This knowledge is almost always acquired “after” the fact, often unwittingly and without conscious or pre-determined intent to collect it. This is the biggest reason so much Nuclear Knowledge is either lost, or very difficult to find later.

- Like Configuration Management (CM) and MRO, the Nuclear Knowledge Management (NKM) program should be commissioned from the first day of NPP design, through construction, and on through operation.

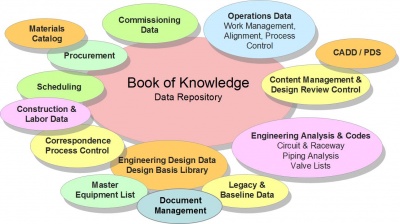

NKM infrastructure and configuration management

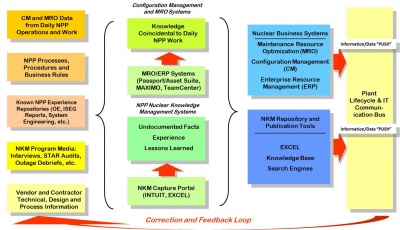

Much of the infrastructure technology and systems established for a comprehensive NPP configuration management (CM) system will also support KM principles, requirements and data. The technology required to implement an NKM programme is based upon the general technology infrastructure required for nuclear MRO, configuration management and general nuclear business operations. This includes raw data, functionality and plant lifecycle management facilities to capture and maintain the plant design basis, design changes, work management, parts and other functions. The technical means of capturing and managing nuclear knowledge closely resembles that required for nuclear business processes and configuration management. A well-formulated configuration management infrastructure will already have a large portion of the functionality and features required for knowledge management as well, and thus should be part of a greater technology infrastructure and system. The proper CM technology solution offers the ideal facility from which to manage nuclear knowledge and make the most of the data and information collected.

Assuming the NPP has a well-developed technology and information infrastructure as described above, the principal difference between baseline nuclear information systems and those requiring modification for NKM is when no KM features and processes have existed previously. Technology solutions that best support knowledge management should offer the following capabilities:

- Capture knowledge as it is utilized and communicated in daily plant activities;

- Be designed to identify and validate knowledge items, as opposed to data or information.

- Make CM elements determined to be knowledge available, accessible and provided for daily use by all NPP staff;

- All NPP users should understand and be comfortable with the system;

- Be based on an NPP — or owner-wide IT solution utilizing a control network such as plant lifecycle management (PLM).

Types of Nuclear Knowledge in NPP's

Explicit Knowledge from Daily NPP Operations: Information, Facts, Design Data and Operating Experience acquired, reviewed, corrected and verified as part of normal NPP operation, then recorded and documented to maintain plant configuration. This process includes Engineering Design, Parts and Procurement, Work Orders and Maintenance, Health Physics, Quality Systems, and other Configuration Management (CM), MRO (Maintenance Resource Optimization) and ERP (Enterprise Resource Management) nuclear business systems.

Latent or Implicit Knowledge: Information, Experience and Knowledge accumulated over time by personnel, which may or may not have been formally recorded or documented. These may be latent memory items or “tribal knowledge”, or may be contained in NPP documentation but not recognized or identified because it is difficult to locate, not properly tracked by the NPP CM system, or unverified.

Nuclear Knowledge Management (NKM) Stages

NKM Lifecycle: First Day of Design forward though Decommissioning

- Identification of Knowledge Sources

- Collection of Knowledge

- Review/Collation into Meaningful Context and Background

- Storage and Retention of Verified Knowledge

- Publication on Demand (Timely and Easy Access)

CM and NKM Convergence in NPP Operations

Configuration Management and Nuclear Knowledge Management converge in the following NPP processes:

- Configuration Management and Asset Management Data

- Design Basis Library and Repository

- NPP Engineering “content and change history” for NPP Design Basis

- NPP Business Rules and Processes

- Asset, Project and Financial Management

- Safety Impact

- Exposure/ALARA

- Plant Production/Availability

- Component Lifecycle/MRO

- Cost and Physical Asset Management

- Regulatory and Programs

- License Impact

Besides NPP Plant Data, how should these tools for Knowledge Capture and Management be best utilized?

- NPP Legacy Documents and Data

- Apprenticeship Programs

- Information Portals, such as SAP and Sharepoint

- Wiki’s, Blogs, Notes, Discussion Forums

- EDR and Engineering Design Review Process Control

- Plant Life Cycle Management (PLM)

Knowledge Management Systems benefit from NPP CM and MRO systems best when you have the appropriate:

- Technology - Computers, Software, IT Architecture.

- Organization - Bottom-Up Information Flow; Accountability and Sense of Teamwork.

- Processes - Ensures Communication of Knowledge Occurs as Normal Part of Work.

- Procedures - Enforces Organization and Communication Requirements.

- Training - Plant Staff Become Aware of Knowledge Needs and Requirements.

- Work Culture - NPP Personnel Relate to Each Other to Maximize Exchange of Experience.

- Infrastructure - Plant Lifecycle Management (PLM) Integrates Knowledge Exchange into Daily Plant Work.